A combination of high-quality coal

and the craftsmanship of swordsmiths.

Located in the southwest of Nagasaki City,

nestled in a bay on a peninsula near the coal mine islands,

lies a small fishing town known for its Kayaki knives.

Once home to around 30 blacksmith workshops,

only a few remain today.

Here, you can experience the craftsmanship of knife-making,

a skill passed down for over 100 years,

rooted in the tradition of swordsmithing.

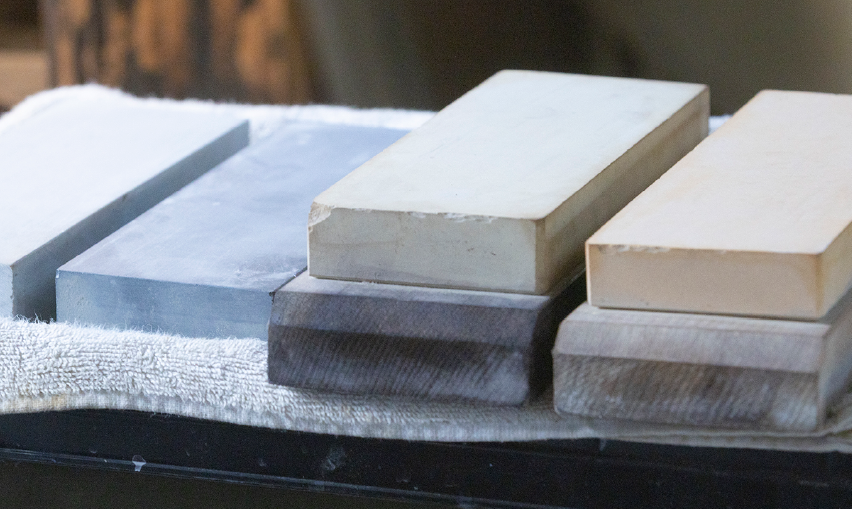

Kayaki, known for its high-quality clay called yakibatsuchi that regulates the toughness and hardness of blades, was an ideal location for sword and tool production from the Edo period. Additionally, the area’s constant underground temperature, maintained year-round, further contributed to the creation of fine blades. To enhance the strength of tools such as knives, iron was heated to over 1,000°C and then hammered in a process requiring intense heat. After the Meiji era, the high-quality coal mined from Takashima and Hashima (Battleship Island) off the coast of Nagasaki was used as fuel. It is also said that tools used in mining, among other items, were often made by Kayaki blacksmiths, whose products were highly valued.

Each knife is a unique, one-of-a-kind creation in the world.

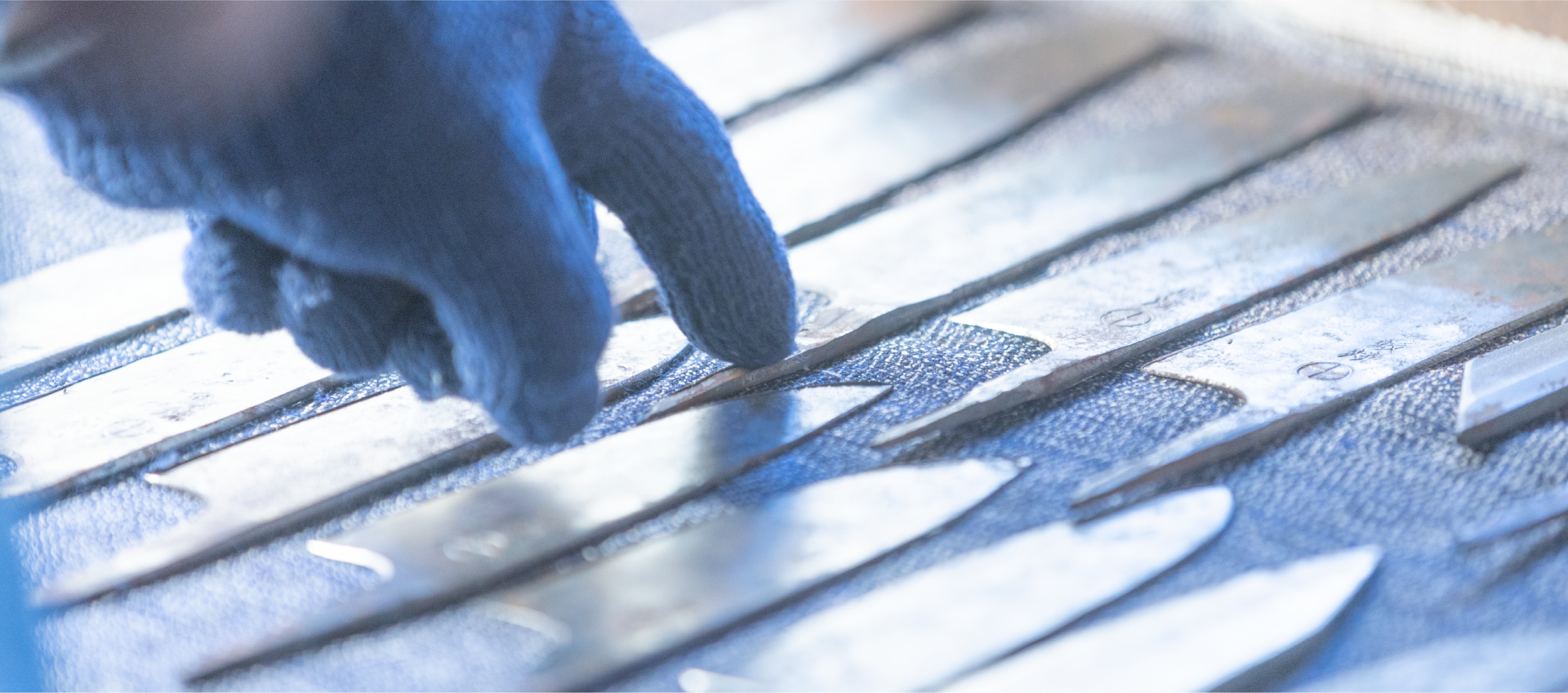

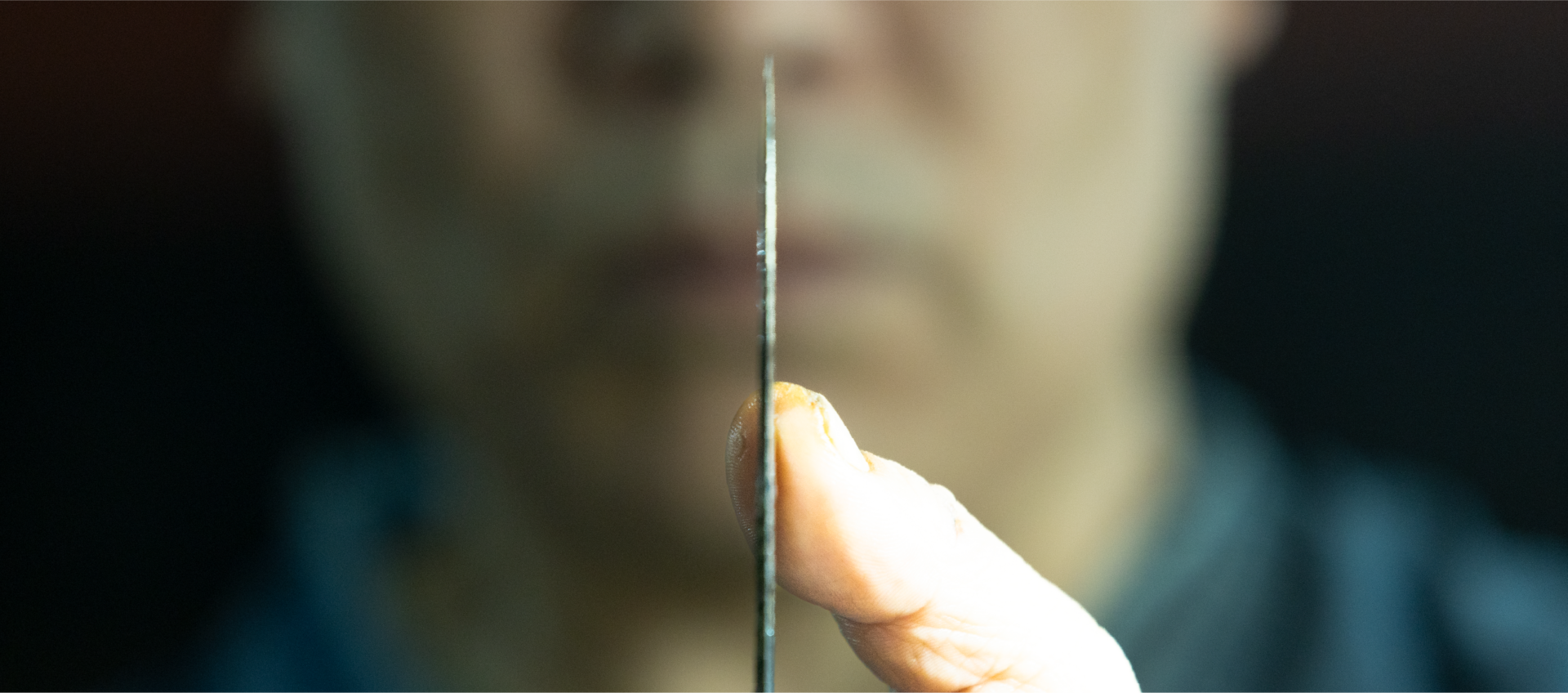

Working in temperatures that can reach 60°C, the craftsperson strikes the blade with precision near the fire, shapes it with a grinding tool that sparks with each turn, and repeatedly sharpens the edge on various natural whetstones, checking its sharpness with their fingers. With no blueprints to follow, this skill has been passed down through generations of experience. Experiencing this process firsthand allows you to truly appreciate the profundity of traditional craftsmanship.

Through this experience, we aim to convey the rich appeal of knife-making, and by increasing the number of knives that reach a wider audience, we contribute to the transmission of the swordsmith’s craftsmanship to future generations.

One undergoes rigorous training

until a sense of gratitude blossoms.

The experience is fully supported, allowing you to take part with confidence and peace of mind.

The third-generation swordsmith, who regained his craftsmanship by training his left hand after a stroke robbed him of the use of his dominant right hand, now works alongside the fourth-generation swordsmith, Kodai, to share the true essence of knife-making while expressing daily gratitude.

When his father, Kazuhisa, fell ill, Kodai made the decision to carry on as the fourth-generation swordsmith. While continuing his own work, he took on the responsibility of mastering the craft, particularly overseeing the fire-based processes and the rough sharpening stages.When his father, Kazuhisa, fell ill, Kodai made the decision to carry on as the fourth-generation swordsmith. While continuing his own work, he took on the responsibility of mastering the craft, particularly overseeing the fire-based processes and the rough sharpening stages.

Assessing the sharpness by the touch of the fingertips.

The shape of a knife changes depending on the size of the hand and the items it is intended to cut. Even a single all-purpose knife will have slight variations in blade length and shape. This is a reflection of the belief that, because each knife is unique, there is surely one that will suit someone perfectly. Finding the knife that fits your hand is another joy of Kayaki knives.

At the age of 18, Kazuhisa began his apprenticeship under his father and took over as the third-generation swordsmith at 36. Since then, he dedicated himself fully to perfecting his craft. However, in 2018, he suffered a stroke that left the right side of his body, including his dominant right hand, paralyzed. Despite moments of doubt, where he wondered if he could continue, he remained grateful for being alive and focused on rehabilitation, determined to give back to his family and customers. Today, he is able to craft knives using only his left hand. Inspired by his father’s perseverance, his son, Kodai, has vowed to carry on as the fourth generation, training under his father’s guidance. Kazuhisa is passionate about passing on the value of Kayaki knives to the next generation.

Quickly shaping the iron while it is still glowing red-hot.

Making knives with the left hand, the opposite of the dominant hand.

Kuwahara Blacksmith Workshop

Address: 1532 Kayaki-machi, Nagasaki City

Opening Hours: 9:00 a.m. to 5:00 p.m.

Parking: Available